In Part 1 and Part 2 of this series of articles on brushless DC (BLDC) motors, we looked at the applications and advantages of BLDC motors and how graphene-based Hall effect sensors from Paragraf can help with making them more efficient.

The use of BLDC motors is widespread across household, commercial and industrial applications. The number of motor units shipped worldwide being several hundred million and growing fast. The carbon footprint benefit of an improved BLDC motor architecture can be very significant. Electrical equipment manufacturer ABB estimates that brushless motors are responsible for more than 45 percent of global electricity consumption – and that adoption of the highest-efficiency motors would reduce all electricity consumption by as much as 10 percent[1].

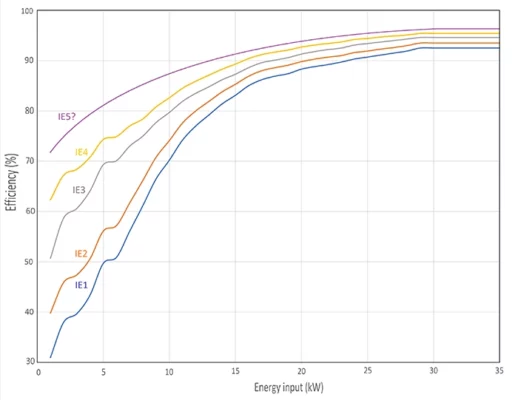

The efficiency of a motor is typically identified by a number that indicates the maximum output power with respect to the input power. Industry standards are used to categorize motors based on their efficiency performance.

What is IE5?

While the efficiency requirements for BLDC motors are regulated by national and regional regulatory bodies, those bodies typically rely on scale set by the International Electrotechnical Commission (IEC), as outlined in IEC 60034-30-1[2]. In the most-recent issue of this document, published in 2018, IEC defines four classes of electric motor efficiency:

- IE1: Standard Efficiency

- IE2: High Efficiency

- IE3: Premium Efficiency

- IE4: Super Premium Efficiency

Since that standard was published, manufacturers have continued to develop more-efficient motors, in anticipation of an additional IE5 (Ultra Premium Efficiency[3]) class – even marketing their motors as IE5 compliant. These IE5 motors are designed to produce up to 20 percent lower energy losses than comparable IE4 motors[4].

Regulations pertaining to energy efficiency will only get tighter and, irrespective of formal regulatory standards, demand for cheaper and cleaner motors will drive the market in the direction of manufacturers whose products can meet that standard.

Who is making IE5 motors and how are they doing it?

There are several manufacturers currently marketing their motors as IE5 ready. Some examples include: ABB, WEG, Hitachi and Nidec. The construction details varies but generally the current generation of IE5 motors rely on upgraded magnetic materials (e.g., amorphous alloys[5] or rare earth materials[4]. Such materials allow the motors to reduce waste but also to enhance performance by varying speed and load, for example in heavy industrial applications like large HVAC units and for pumping fresh water and wastewater.

Could advanced materials – for instance, graphene and other 2D materials – employed in other functions within the motor also provide an answer to manufacturers seeking next-level BLDC energy efficiency?

How does Paragraf get me to IE5?

As we discussed in Part 2 of this series, Hall effect sensors employing graphene as the sensing element boast several advantages over competing Hall sensor technologies. Paragraf’s graphene-based sensors’ high-sensitivity and immunity to in-plane stray fields provide more precise – therefore, more-efficient – position sensing. Additionally, graphene’s 2D structure and exceptional electron mobility reduces the power required to operate the sensor.

These benefits can contribute to the reduction of energy wastage across the whole of the BLDC system. Particularly when used in conjunction with other advanced materials employed in a motor’s construction, graphene Hall sensors present an industry-ready solution for the next step-change in energy efficiency classification.

Paragraf has made energy efficiency a hallmark of our business. Graphene and other 2D materials will be key to making future-generation BLDC motors do more on less.

[1] ABB – Energy Efficiency Movement

[2] IEC 60034-30-1:2014 | IEC Webstore | pump, motor, water management, smart city, energy efficiency

[3] Ultra Premium Efficiency (IE5 Energy-Efficiency Class) Synchronous Reluctance Motor with Fractional Slot Winding | IEEE Conference Publication | IEEE Xplore

[4] Motoring into the IE5 era for energy efficiency | E&T Magazine (theiet.org)